Project Description

| layers of paper winding | 3 |

| The maximum coil diameter | 20mm |

| Minimum coil diameter | 3.3mm |

| Maximum coil thickness | 1.5mm |

| Minimum coil thickness | 0.2mm |

| Fixed mode | Coaxial locking of coiling die in fixed mode |

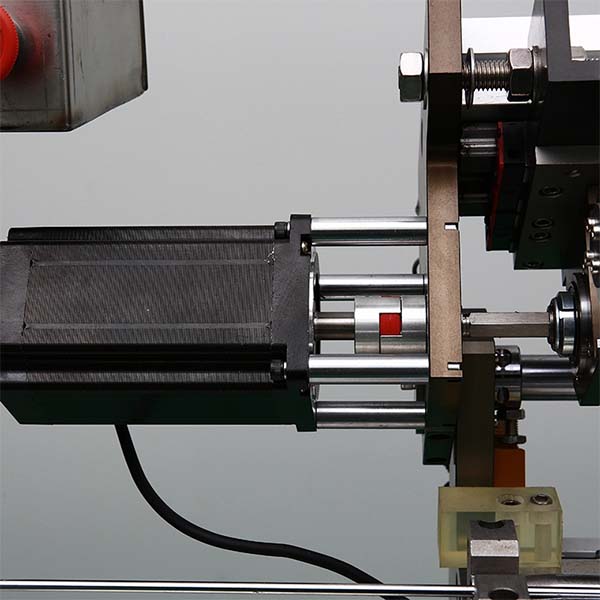

| Winding machine head | two single belt |

| Cutting mode | Cutting mode servo motor cutter, standard 7 sets of manual tool holder |

| Gluing mode | double gluing and single gluing |

| Fixed-length mode | encoder (internal count available) |

| The number of operators | 1 |

| Roll out tube speed | 20-50 m/min |

| Speed control | servo control |

| Input power | 380V three-phase four-wire |

Attached accessories

| Application tools | Included |

| Coil belt | 1 pc |

| Coil mandrel | 1 set |

Control system

| PLC | Single-chip PLC controller |

| Touch screen | HMI willon touch screen |

| Program version | JGFQ-05 |

| Servo system | panasonic 1.5kw, 750W |

| Executive device (contactor, etc.) | China zhengtai products |

| Signal element (photoelectric switch, etc.) | Japanese omron products |

| Synchronous tracking pipe cutting system | Tracking shear system |

Machine size:

| length × width × height | 3000mm×640mm×1600mm |

| Floor area | length × width 8300mm×6000mm |

| Hub diameter | 155mm |

| Hub height | 100mm |

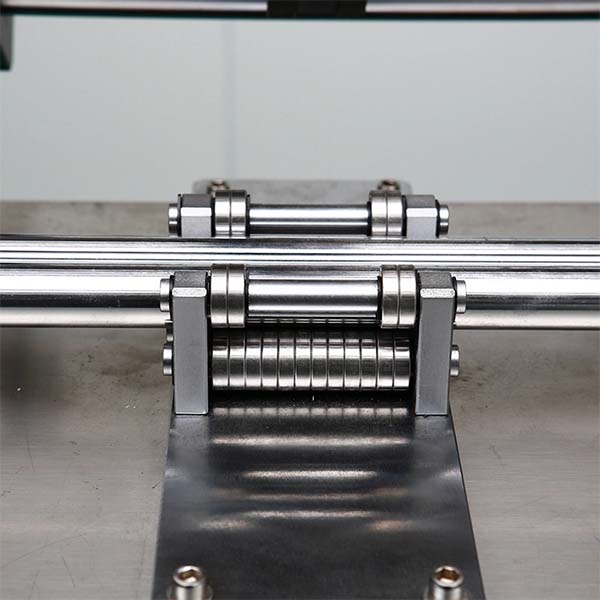

| Minimum wheel base | 450mm |

| Maximum wheelbase | 600mm |

| Weight | 900kg |

Device Equipped

| Automatic fall pipe rack | Electric conveying device |

| Belt tension adjustment | Handwheel adjustment |

| Automatic stop system | Automatic stop when lack of paper |

| Paper lifting system | The paper lifting system breaks off the glue automatically |

| Lubrication system | Paper tape is automatically used for lubrication |

| Paper tape tension adjustment syetem | Constant tension control |

| Paper holder type | Paper holder type overall continuation of the paper holder/storage of 16 meters |

| Coil belt | Coil belt base strap |

5 features of our paper straw making machine

1. The design of the paper Straw machine has been innovated for the stability of production, the quality of products and the convenience of operation, and has many patents

2. Don’t need an air source. Abandon the traditional pneumatic cutting structure, the original all-servo cutting structure, greatly reduce noise and reduce energy consumption

3, Has a patented flexible cutting technology, can ensure smooth product cuts. At the same time, it can improve the durability of the blade. it will ensure the cutting more than 2 million times without sharpening the blades

4, Raw material tension is an important prerequisite for stable production, this equipment has constant tension inside, and can paper tape tension maintain stable in the whole production process.

5, It also designed to have some of the user-friendly functions, such as lack of material down automatically, various capacity statistics, the classification authority set, and so on.

Full motor electric servo motor upgrade the sixth generation, series of paper tube machine, design concept small, simple, stable, high-speed, intelligent, networking.

Standard production paper tube less than 1 inch (inner diameter 25mm) thickness less than 1mm.

Mainly used for the production of paper straw, pen tube, etc., can complete multiple sections of cutting at one time.

Meet the production requirements of food grade products, the production of spiral paper tube from gluing, winding, to the requirements of cutting a complete.